Application

Application

The acronym HEPA stands for High Efficiency Particulate Arrestance

(you may see others using variants for the letter “A” like arresting, arrestor, or even simply air, but they all convert the same basic meaning ‘to capture’)

A ‘true’ HEPA is also known as an ABSOLUTE filter because of its efficiency.

For a filter to be called a True Hepa it must retain and filter out all particles from the air that passes through it down to 0.3 microns in size at an efficiency rating of 99.97%.

The efficiency of a true Hepa does not decrease during its life; it actually increases.

For a filter to be labeled ‘True Hepa’, it must be certified 99.97% efficient in capturing 0.3 microns respirable-size-particles (RSP)

according to the U,S. Millitary standard MIL-STD-282 commonly known as the D.O.P.test.

True Hepa filteration is recognized as one of the must efficient air filteration methods known and proven to remove airborne particles down

to 0.3 microns and are used for the purpose of absolute filtration in nuclear installations, toxin research laboratories, pharmaceutical industry, clean room system, laminar flow working bench, hospital sterile area, space application, man made fibre Industry, food processing zone, biological centres and many other areas.

Construction

Absolute HEPA filters are made out of 100% water and fire-resistant imported micro glass fibre paper. The paper is pleated and the pleats are separated by super fine corrugated aluminium foil and finally fitted in an aluminium frame. Epoxy-based adhesive is used all over from the inside for effective sealing of gaps, and also neo-prene-sponge rubber gasket is provided on the flanges to effectively seal the construction from the outside.

Size

Usually in 150 mm to 300 mm depths, it is also available in wide range of size, capacities and efficiency ratings as per the system requirement.

TECHNICAL DATA

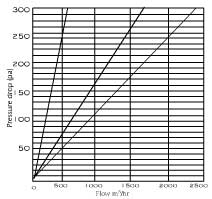

Recomended Air Velocity :0.45 m/sec. to 1.2 m/sec.

Initial Pressure Drop : 20 – 25 mm Wg.

Final Pressure Drop : 75 – 100 mm Wg.

(When Filter needs Cleaning)

Efficiency as per D O P penetration test

As per FED STD. 209 E : 99.97%