- CFI Automatic Viscous Filter

- CFI Rollo-Band Filter

- CFI Dry Fabric Pre- Filter

- CFI All Metallic Viscous Filter

- CFI 4 Ply H.D.P. Panel Filter

- CFI 5 Ply H.D.P. Panel Filter

- CFI Dry Fabric Fine Filter

- CFI Pocket Bag Filter

- CFI High Efficiency Particulate Air Filter (HEPA)

- Air Ventilation Systems

- Air Pollution Control Equipment

- CFI ACTIVATED CARBON FILTERS

CFI Automatic Viscous Filter

Application

Application

CFI Automatic Self-Cleaning Viscous Filter Is used in general ventilation and air conditioning and is specially designed to handle very high volume of air, it is most suitable for areas where the surrounding air contains high dust concentration such as Coal and lignite mines, steel plants, foundries and cement plants.

Construction

The CFI Automatic Viscous Filter is self-cleaning and works in two stages.An oil drop eliminator follows a specially constructed endless Filter Mat.The mat is made from steel wire mesh whereas the oil drop eliminator does not contain wire mesh. The whole unit is supported on a steel framework.Suitable oil sump and sludge containers are also provided. A geared motor with fractional horse-power with very low RPM controlled by time relay drives the unit. The filter unit can be directly driven or indirectly driven. A direct unit can drive upto two indirect units.

Size

| SIZE | HIGHT OF VISIBLE MAT (mm) | FILTERATION AREA (Sq.Mtr.) | FLOW CAPACITIES (Cu.Mtr.Hr.) |

|---|---|---|---|

| 009 | 820 | 0.738 | 6650 |

| 013 | 1180 | 1.036 | 9350 |

| 015 | 1360 | 1.224 | 11000 |

| 019 | 1720 | 1.548 | 14000 |

| 023 | 2080 | 1.873 | 17000 |

| 029 | 2620 | 2.37 | 21500 |

| 037 | 3190 | 2.871 | 26000 |

| 041 | 3610 | 3.321 | 30000 |

| 051 | 4790 | 4.311 | 40000 |

THE FLOW CAPACITIES INDICATED ABOVE ARE AT A FACE VELOCITY OF 2.5 Mtr./Sec.

CFI Automatic Viscous Filter comes in various sizes with mat height ranging from 820 mm to 4790 mm and width 900 mm.

Technical Data

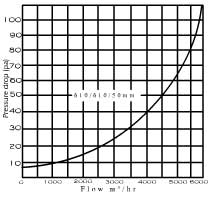

Recomended Air Velocity : 2.5 m/sec. to 2.6 m/sec.

Initial Pressure Drop : 4 – 5 mm wg

Final Pressure drop : 8 – 10 mm wg

Average Synthetic Dust Wt. Arrestance : 80 %

As per BS. EN. 779 & ASHRAE 52.1

Average Atmospheric Dust Efficiency (Micronic) : 40 %

Using Laser-based Particle counter

CFI Rollo-Band Filter

Application

Application

CFI Rollo-Band Filter is used in air-conditioning and ventilation systems where excellent level of filtration is required. The air going into air-conditioning units and processed air is purified through this filter. Also used as pre-filter in Pharmaceutical and synthetic fibre industries, steel and fertilizer plants and nuclear plants.

Construction

CFI Rollo-band filter is made of fibre glass/polyester media treated with special thi-oxy-tropic gel resin and fitted in a steel frame. The units has a pressure switch, which automatically activates and rolls down the media when the differential pressure increases. Limit switch and hooters are provided to indicate the end of media. A fractional horse powered geared motor with very low RPM dives the unit.

Size

CFI Rollo-Band Filters are available in wide range of sizes. Capacities and efficiency rating as per the system requirement.

CFI Rollo-Band Filters are available in wide range of sizes. Capacities and efficiency rating as per the system requirement.

Technical Data

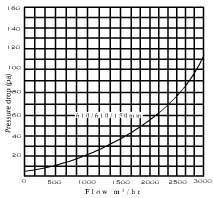

Recomended Air Velocity : 2 m/sec.

initial Presure Drop : 8-12 mm Wg.

Final Pressure Drop : 45-50 mm Wg.

Average Synthetic Dust Wt. Arrestance : 90-95%

As per BS. EN. 779 & Ashrae 52.1

Average Atmospheric Dust Efficiency ( Micronic ) : 45 % to 80 %

using Laser-based Particle Counter

CFI Dry Fabric Pre- Filter

Application

Application

CFI Dry Fabric Pre-Filter is used in air conditioning, compressor air intake and general ventilation as a pre filter at the atmosphere end.

Construction

CFI Dry Fabric Pre-Filter is made of one layer washable type non-woven polyester media with HDP backing on both sides and stiched together in a deep crimped formation to provide maximum filteration area. The media is separated by G.I. spacers to allow uniform flow and finally fitted in G.I. Filter Frame.

Size

The size of this filter is generally 610 x 610 x 150 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

Technical Data

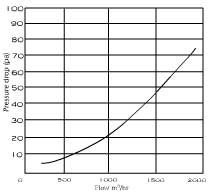

Recomended Air Velocity :2 m/sec. to 2.5 m/sec.

Initial Pressure Drop : 4 mm Wg.

Final Pressure Drop : 8 mm Wg.

(When Filter needs Cleaning)

Average Synthetic Dust Wt. Arrestance : 85%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

45% Using Laser-based Particle Counter

CFI All Metallic Viscous Filter

Application

Application

CFI All Metallic Viscous Filters are washable type filters used as pre-filters for general ventilation and air conditioning.

Construction

The CFI All Metallic Viscous Filter is constructed using 5 layers of G.I. wire mesh interspersed with 2 crimped layers and 3 flat layers. The media is supported with expanded metal from both sides as reinforcement and fitted in 50 mm metal frame. the filter media ensures maximum filteration area resulting in nominal differential pressure and high dust holding capacity. The filter is required to be impregnated with oil before use.

Size

CFI All Metallic Viscous Filter comes in various sizes but generally the size is 610 x 610 x 50 mm.

CFI All Metallic Viscous Filter comes in various sizes but generally the size is 610 x 610 x 50 mm.

Technical Data

Recomended Air Velocity :2 m/sec. to 2.5 m/sec.<br>

Initial Pressure Drop : 4-6 mm Wg.

Final Pressure Drop : 8-10 mm Wg.

Average Synthetic Dust Wt. Arrestance : 85%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

40% Using Laser-based Particle Counter

CFI 4 Ply H.D.P. Panel Filter

Application

Application

CFI 4 Ply HDP Panel Filter is used for air conditioning, compressor air intake and general ventilation as a pre-filter to fine filter.

Construction

CFI 4 Ply HDP Panel Filter is made of 4 layers washable type of high density Polyethelene media, stiched together in a deep crimped formation to provide maximum filteration area. The media is separated by G.I. spacers and is backed by expanded metal on one side. Finally, it is fitted in G.I. filter frame.

Size

The size of this filter is generally 610 x 610 x 50 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

The size of this filter is generally 610 x 610 x 50 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

Technical Data

Recomended Air Velocity : 2.5 m/sec.

Initial Pressure Drop : 4 mm Wg.

Final Pressure Drop : 8 mm Wg.

(When Filter needs Cleaning)

Average Synthetic Dust Wt. Arrestance : 80%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

40% Using Laser-based Particle Counte

CFI 5 Ply H.D.P. Panel Filter

Application

Application

CFI 5 Ply HDP Panel Filter is used in air conditioning, compressor air intake and general ventilation as a pre-filter to bag filter.

Construction

CFI 5 Ply HDP Panel Filter is made of 5 layers of washable type high density Polyethelene media, stiched together in a deep crimped formation to provide maximum filteraton area. The media is separated by G.I. spacers and is backed by expanded metal on one side. Finally, It is fitted in G.I. filter frame.

Size

The size of this filter is generally 610 x 610 x 150 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

The size of this filter is generally 610 x 610 x 150 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

Technical Data

Recomended Air Velocity : 2.5 m/sec.

Initial Pressure Drop : 6.5 mm Wg.

Final Pressure Drop : 14 mm Wg.

(When Filter needs Cleaning)

Average Synthetic Dust Wt. Arrestance : 85%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

45% Using Laser-based Particle Counter

CFI Dry Fabric Fine Filter

Application

Application

CFI Dry Fabric Fine Filter is used in air conditioning, compressor air intake, paint booth and ventilation systems as a pre-filter to 1-micron Bag filters or sub-micronic HEPA filters.

Construction

CFI Dry Fabric Fine Filter is made of one layer washable type super fine non-woven polyester media with metalic backing and stitched together in a deep crimped formation to provide maximum filteration area. The media is separated by G.I. spacers to allow uniform flow and finally, it is fitted in metallic filter frame.

Size

The size of this filter is generally 610 x 610 x 150 mm and 610 x 610 x 300 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

The size of this filter is generally 610 x 610 x 150 mm and 610 x 610 x 300 mm in both Cassette (Box) type and Fanged type, but it can be made in any other size according to the requirement of the system.

Technical Data

Recomended Air Velocity : 1.5 m/sec. to 2 m/sec.

Initial Pressure Drop : 6-8 mm Wg.

Final Pressure Drop : 16-18 mm Wg.

(When Filter needs Cleaning)

Average Synthetic Dust Wt. Arrestance : 98%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

55% to 85% Using Laser-based Particle Counter

CFI Pocket Bag Filter

Application

Application

CFI Pocket Bag Filters are designed for air conditioning and general ventilation application. Typical users are hospitals, pharmaceutical plants, power stations and industries which require very high efficiency of filteration.

Construction

CFI Pocket Bag Filters are constructed from three distinctive filter media each fulfilling a specific duty. The first stage is a glass fibre which acts as a pre-filter and at the same time gives a large dust holding capacity for a longer life. The second stage is a super fine filter media which captures dust particles as low as 1 microns and finally there is a cerex backing which prevents fibre migration. The bags are finally fitted in metallic.

Size

The bags are fitted in header frames generally of the size 600 x 600 mm(4 pockets) and 600 x 300 mm(2 pockets). The bags come in 5 different lengths: 380, 550, 635, 750, 900 mm.

Technical Data

Recomended Air Velocity : 1.2 m/sec. to 2 m/sec.

Initial Pressure Drop : 10 – 12 mm Wg.

Final Pressure Drop : 20 – 25 mm Wg.

(When Filter needs Cleaning)

Average Synthetic Dust Wt. Arrestance : 98% – 99%

As per BS. EN. 779 & ASHRAE 52.1 .

Average Atmospheric Dust Efficiency (Micronic) :

95% – 98% Using Laser-based Particle Counter

CFI High Efficiency Particulate Air Filter (HEPA)

Application

Application

The acronym HEPA stands for High Efficiency Particulate Arrestance

(you may see others using variants for the letter “A” like arresting, arrestor, or even simply air, but they all convert the same basic meaning ‘to capture’)

A ‘true’ HEPA is also known as an ABSOLUTE filter because of its efficiency.

For a filter to be called a True Hepa it must retain and filter out all particles from the air that passes through it down to 0.3 microns in size at an efficiency rating of 99.97%.

The efficiency of a true Hepa does not decrease during its life; it actually increases.

For a filter to be labeled ‘True Hepa’, it must be certified 99.97% efficient in capturing 0.3 microns respirable-size-particles (RSP)

according to the U,S. Millitary standard MIL-STD-282 commonly known as the D.O.P.test.

True Hepa filteration is recognized as one of the must efficient air filteration methods known and proven to remove airborne particles down

to 0.3 microns and are used for the purpose of absolute filtration in nuclear installations, toxin research laboratories, pharmaceutical industry, clean room system, laminar flow working bench, hospital sterile area, space application, man made fibre Industry, food processing zone, biological centres and many other areas.

Construction

Absolute HEPA filters are made out of 100% water and fire-resistant imported micro glass fibre paper. The paper is pleated and the pleats are separated by super fine corrugated aluminium foil and finally fitted in an aluminium frame. Epoxy-based adhesive is used all over from the inside for effective sealing of gaps, and also neo-prene-sponge rubber gasket is provided on the flanges to effectively seal the construction from the outside.

Size

Usually in 150 mm to 300 mm depths, it is also available in wide range of size, capacities and efficiency ratings as per the system requirement.

TECHNICAL DATA

Recomended Air Velocity :0.45 m/sec. to 1.2 m/sec.

Initial Pressure Drop : 20 – 25 mm Wg.

Final Pressure Drop : 75 – 100 mm Wg.

(When Filter needs Cleaning)

Efficiency as per D O P penetration test

As per FED STD. 209 E : 99.97%

Air Ventilation Systems

Bag Filter Unit

our bag filters are compact, self-cleaning, continuous duty dust collection system that economically meets the need of most industrial application. The advanced system utilizes pulse jet cleaning, that effectively dislodges the captured dust from then bags and cleans the filter while the systems stays on line. With minimal pressure drop, our bag filters maintain 99.9% filtration efficiency. With versatile construction & selection from a variety of filter media, we can meet any manufacturing dust collection application such as food processing, wood working, molding, grinding, polishing, rock / stone / glass operations, secondary smelting, pharmaceuticals, metal working, etc.

our bag filters are compact, self-cleaning, continuous duty dust collection system that economically meets the need of most industrial application. The advanced system utilizes pulse jet cleaning, that effectively dislodges the captured dust from then bags and cleans the filter while the systems stays on line. With minimal pressure drop, our bag filters maintain 99.9% filtration efficiency. With versatile construction & selection from a variety of filter media, we can meet any manufacturing dust collection application such as food processing, wood working, molding, grinding, polishing, rock / stone / glass operations, secondary smelting, pharmaceuticals, metal working, etc.

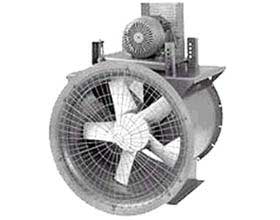

Axial Flow Fan

Our axial fans are of high efficiency design resulting in power saving. We offer a variety of axial fans such as tube axial type with motor mount, medium and large axial type with pedestal foot mount having independent shaft & bearings, direct / pulley belt driven. We offer aerofoil cast blades for clean gas application / plate bladed design for dusty gas. The blades are of fixed or variable pitch adjustment depending on the application.

Centrifugal Fans

Our Centrifugal Fans have High Volume, Low Pressure . We have in our range SISW and DIDW with flow upto 1,00,000 CMH widely used for ventilation, pressurization, Drying applications etc.The manufacturing range upto 100HP motor fan.Various material of construction like MS/ SS / PP FRP / FRP etc.

Features of Centrifugal Fans are:

- Capacity from 50 CFM to 3,50,000 CFM

- Wg. pressure capacity from 0.25 to 52

- Can be used up to 600 degree centigrade temp

- Quiet operational

- Optimum functionality

- Available in modern design

Air Pollution Control Equipment

Fume Extractors & Dispensers

Fume Extractors & Dispensers

We are fabricating different types of Fume Extractors and Dispenser which are available in different suction capacities. These are mostly used for Chemical Fumes Generated in the their work place. The fumes are filtered to give out clean and healthy air from this unit.

The features of these Extractors and Dispensers are:

- Available in different specifications

- High suction capacity

- Heat resistant

- Corrosion resistant

- Can be easily installed

AIR WASHER UNIT

We manufacture and export a range of air washer. The typical applications are in textile mills, jute mills, air cooling and ventilation requirements. They are available in modular designs (panel type) and standard units.

We manufacture and export a range of air washer. The typical applications are in textile mills, jute mills, air cooling and ventilation requirements. They are available in modular designs (panel type) and standard units.

CYCLONE SEPERATORS

Fiber and dust will exist, and our separators may be used in place of or in front of filters. This allows for larger particles to be broken down before the air is filtered. Also, cyclone separator systems are used to separate two immiscible fluids with different densities within a confined amount of space.

Fiber and dust will exist, and our separators may be used in place of or in front of filters. This allows for larger particles to be broken down before the air is filtered. Also, cyclone separator systems are used to separate two immiscible fluids with different densities within a confined amount of space.

CFI ACTIVATED CARBON FILTERS

EFFICIENCY COMBINES WITH FLEXIBILITY

APPLICATION

By means of the aimed utilization of certain characteristics of activated carbon we have been in a position to reach the highest status in the clean-keeping of air from gaseous noxious matter through the application of equipments, developed by ourselves CFI Activated Carbon filter are used for eliminating noxious matters from the Air.

By means of the aimed utilization of certain characteristics of activated carbon we have been in a position to reach the highest status in the clean-keeping of air from gaseous noxious matter through the application of equipments, developed by ourselves CFI Activated Carbon filter are used for eliminating noxious matters from the Air.

CONSTRUCTION

CFI Activated Carbon filters are made of fine Non woven polyester media impregnated with powder coated treated with PU base materials and finally fitted in Metallic frame.

Size of the filter is generally in the range of 610 x 610 x 100 mm to 610 x 610 x 300 mm Cassette Type ( Box Type )

TECHNICAL DATA

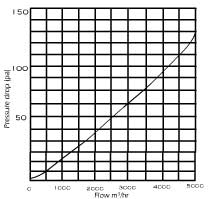

Recommended Average Air velocity : 0.5 m/sec to 2.0 m/sec.

Velocity through Media : 0.18 m/sec.

Pressure drop : 15-20 mm w.g. ( Initial)

Average absorption : 85% to 90%

In practise this means :

- Lower quantity of activated carbon for the same performance

- Higher admissible velocities of air

- Uniform pressure drop on a low level

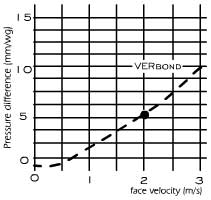

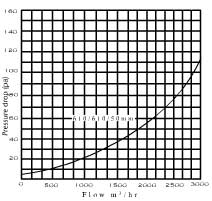

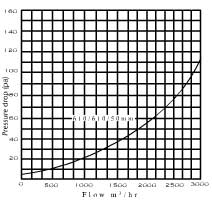

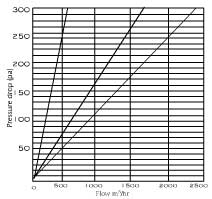

GRAPH